Call Anytime

MacLeanDixie offers a broad range of steel helical foundation piles used to support solar installations.

Features and Benefits of MacLeanDixie Helical Foundation Systems:

Features and Benefits of MacLeanDixie Helical Foundation Systems:

- Used for tension, compression and overturning loads

- Installed with no vibration

- Installs in one visit to the job site -- no waiting, curing or assembly of materials

- Minimal soil disturbance - No spoils

- Can be installed in any weather

- Accurate positioning -- matches system tolerances

- Helical piles / anchors may be removed

- Environmentally friendly - a "Green" foundation.

- Available standard hot dip galvanized ASTM A-153 or black (not coated)

ICC AC358 Acceptance Criteria For Helical Foundation Systems and Devices Tests:

- Full scale Compression Load Test in sand and clay

- Full scale Tension Load Test in sand and clay

- Full scale Lateral Load Test

- Shaft Torsion

- Helix Torsion

- Coupling Rigidity

- Helix Capacity

- Bracket Capacity

Helical Piles

Earthwise Manufacturing provides a full range of specialized equipment for the installation of helical piles, ensuring you have the right tools for the job, no matter the project size or complexity. When you're ready to invest in equipment, we go beyond just selling you a product. Our team will consult with you to understand the specific machines you currently own and the types of work you plan to undertake. This allows us to recommend the most suitable equipment options tailored to your needs and budget.

Types of Equipment for Helical Pile Installation:

-

Hydraulic Drive Heads: These powerful units are the core of helical pile installation. Hydraulic drive heads are used to apply the necessary torque to screw the piles into the ground. Depending on the size and type of the project, we offer a range of drive heads with varying torque capacities, ensuring you can tackle both light residential projects and heavy-duty industrial installations.

-

Torque Monitoring Systems: Accurate torque monitoring is crucial for verifying that the helical piles are installed to the correct specifications. We provide advanced torque monitoring systems that give real-time feedback, ensuring each pile is installed to the exact load-bearing requirements.

-

Excavators and Skid Steers: The choice of base machine—whether an excavator or a skid steer—depends on the project's scale and site conditions. Excavators are ideal for larger, more demanding installations, providing the reach and power needed for deep installations. Skid steers, on the other hand, are perfect for smaller or more confined spaces, offering flexibility and maneuverability.

-

Adapters and Extensions: To accommodate different project needs, we supply a variety of adapters and extensions. These are crucial for connecting the drive heads to the base machine and for reaching the required depths during installation. Our adapters and extensions are compatible with a wide range of equipment, ensuring seamless integration with your existing tools.

-

Load Testing Equipment: Ensuring the integrity of your installation is vital. Our load testing equipment allows you to verify the load capacity of each pile after installation, giving you and your clients confidence in the foundation's stability and durability.

We understand that every project is unique, which is why we offer an extensive selection of equipment to suit any job. Whether you're working on residential, commercial, or industrial projects, we have the tools you need to get the job done right. Contact us today to learn more about our helical pile installation equipment and how we can help you select the best options for your specific requirements.

Helical Piles

At Earthwise Manufacturing, we are committed to ensuring that our products are installed with the same precision and quality with which they are manufactured. To achieve this, we certify all our installers through MacLean Power Systems, ensuring they meet our high standards. The certification process involves a comprehensive classroom course, culminating in a written exam. This rigorous training educates installers on our products, proper installation techniques, and the various applications they may encounter. In addition to classroom certification, we provide our certified installers with the following exclusive benefits:

Partnering with Earthwise Manufacturing

- Field training and on-site support

- 24/7 Technical assistance

- Design and Engineering consulting services

- Exclusive discounts on specialized equipment

- Volume-based discounts on helical and anchoring products

- Marketing support, including product literature, website presence, and technical presentations

Become a Certified Installer

If you’re looking to expand your business with Earthwise Manufacturing’s top-tier foundation products, contact us today to schedule a meeting. During our initial consultation, we’ll answer all your questions, give you a tour of our facility, and introduce you to our comprehensive product lines. We’ll also discuss your current projects to ensure a mutually beneficial partnership.

Helical Piles

Helical Pile Design Recommendations

Interline Industrial Supplies’ staff has been involved in thousands of projects ranging from simple new construction applications to out of the box applications such as using large diameter helical piles as solider piles during support of excavation. No matter what the application, our engineering staff can provide you with complimentary design recommendations, which include the following services:

- Preliminary helical pile design in both tension and compression

- Job-notes and product specifications

- Value engineering and cost analysis

- Technical support

- Installation guidelines

In addition to the services listed above, we work closely with a number of design professionals who can aid in your helical pile design, as well as stamp and seal your helical pile designs.

MDRS Web-Based Software

Designing helical piles, whether in tension or compression, can be a very complicated procedure, however MacLean Real-Time Design (MDRS) makes this process straightforward. MDRS allows the user to input the soil parameters, design loads, and other relevant project details for a specific application in order to make simple work of otherwise convoluted calculations. The result is a quick and easy helical pile design that you can be confident in. Contact us today to schedule an MDRS training class or let us do the work for you so you can keep your projects on time and on budget!

“Strength Squared™” Coupling System

The shape of a pipe helical pile presents a major issue during installation: how to screw a round pipe into the ground. The common answer to this is to bolt the round pipe to a round drive tool, which presents further complications such as elongated bolt holes, sheared bolts, and reduced installation torque capacities. MacLean Power systems has solved all of these issues with the development of their patented “Strength Squared™” coupling system. The “Strength Squared™” utilizes a square engagement system on all of their helical piles, including round pipe piles. This engagement transmits all of the torque imparted to the pile to the corners of the “Strength Squared™” coupling system making elongated bolt-holes and sheared bolts a thing of the past. In addition, since the “Strength Squared™” system eliminates the stress on the pile itself, the pile can now be installed to achieve the maximum capabilities of the pipe material, rather than being limited to the strength of the bolts and bolt-holes.

ICC Approval

MacLean Dixie was one of the first helical pile manufacturers to obtain an ICC approval on their helical products and today continues to offer the largest selection of ICC approved material in the industry.

Helical Piles

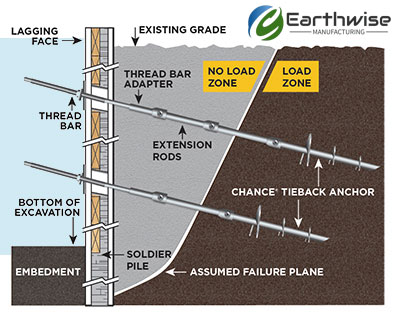

Helical piles or anchors provide a fast, cost-effective, and straightforward solution for virtually any tieback project. Whether you're working on small retaining walls, marine bulkheads, or large-scale excavation support, there is a helical pile suited for your project needs. With single anchor capacities of up to 150,000 lbs, helical anchors are robust enough to handle the most demanding tasks. Additionally, these anchors are ideal for straightening bowing foundation walls, offering a versatile application across various structural challenges.

The installation process for helical tiebacks is remarkably efficient. These anchors are simply rotated into the soil, without the need for concrete, making them an immediate and cost-saving solution. The ability to proof test and load the tiebacks immediately after installation not only accelerates project timelines but also ensures reliability and performance from the outset.

Advantages of Helical Tiebacks

- No vibration: The installation process causes no vibrations, making it suitable for sensitive environments.

- Limited access installations: Can be installed in confined spaces where traditional methods may not be feasible.

- High productivity rate: Helical tiebacks are quick to install, significantly reducing project time.

- Immediate proof testing: Tiebacks can be tested immediately after installation, providing real-time verification of load capacity.

- Immediate loading: Ready to bear loads as soon as installation is complete, saving both time and money.

- No spoils: The installation process generates no spoils, reducing cleanup and disposal costs.

- Year-round installation: Suitable for installation in any weather, ensuring project continuity.

- Predictable and reliable performance: Helical tiebacks offer consistent results, even in challenging soil conditions.

- Lightweight equipment: Installed with a variety of lightweight, portable equipment, making the process more flexible and efficient.

- Small crew: Requires a minimal crew for installation, reducing labor costs.

- Permanent or temporary use: Helical tiebacks are versatile enough for both permanent and temporary applications.

- Adaptable terminations: Offers various termination options to suit most design requirements.

Helical Piles