Call Anytime

Helical Piles

What is a Helical Pile?

Helical piles, also known as helical anchors, helical piers, or screw piles, represent a cutting-edge foundation solution. These innovative systems are engineered to bypass weak soil layers, effectively transferring the structural loads to deeper, more competent load-bearing soils. Helical piles offer a cost-effective and efficient way to support structures in challenging soil conditions, while also significantly enhancing the load-bearing capacity of existing foundations. Their versatility makes them ideal for a wide range of projects, particularly those where noise, vibration, soil disturbance, or site access pose challenges. Whether used in new construction or retrofitting projects, helical piles provide a robust and reliable solution that adapts to various environmental and logistical constraints.

Helical Pile Installation

The installation process of helical piers is both straightforward and highly effective. It involves applying controlled torque to rotate the helical pile into the ground, similar to driving a self-tapping wood screw. This method ensures a secure and stable foundation by penetrating deep into the soil layers, anchoring the pile until it reaches the desired load-bearing capacity. The torque applied during installation directly correlates to the pile's capacity, offering a real-time measure of performance and ensuring that the foundation is built to last.

Parts of a Helical Pile

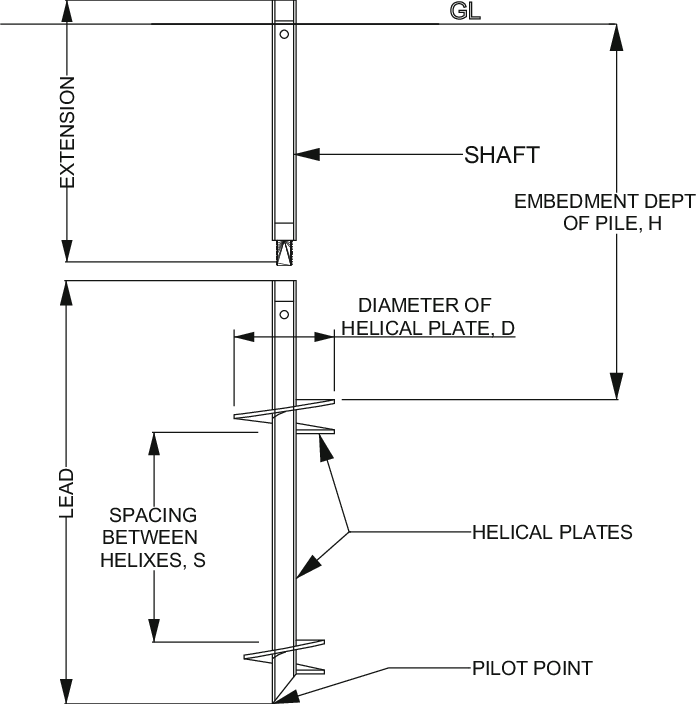

Lead Section

The lead section is the critical first component of the helical pile system. It initiates the installation by penetrating the soil and transferring the load from the central steel shaft to the surrounding soil. This transfer is achieved through helical bearing plates, known as helices, which are precision-welded to the shaft. The helices are designed with a specific pitch, allowing the pile to be smoothly rotated and driven into the ground with minimal soil disturbance. The lead section's design ensures that the load is distributed evenly, providing a strong and stable foundation that can withstand significant forces.

Extensions

Helical pile extensions are essential for reaching the required depth and torque during installation. These extensions consist of a central steel shaft, equipped with metal couplers at each end—one male and one female. The first extension is securely bolted to the lead section, and additional extensions are added as necessary. This modular approach allows the helical pile to achieve the optimal depth and load-bearing capacity, ensuring that the foundation is both robust and adaptable to varying soil conditions.

Terminations

Terminations are the final component in the helical pile system, connecting the pile or anchor to the structure it supports. These connections are critical, as they ensure the transfer of loads from the structure to the helical pile is both secure and effective. Various types of terminations are available, each tailored to specific applications and structural requirements. This versatility allows helical piles to be used in a wide range of projects, from residential buildings to large-scale industrial installations.

Advantages of Helical Piles

- Rapid installation: Helical piles can be installed quickly, reducing construction time and labor costs.

- Versatility: Suitable for a wide variety of soil conditions, making them adaptable to most environments.

- Ease of installation: Installed using a wide range of readily available equipment, requiring no specialized machinery.

- Multi-directional load resistance: Helical piles are capable of resisting tensile, compressive, and shear (lateral) loads.

- No spoils: Installation generates no spoils, eliminating the need for disposal and minimizing environmental impact.

- Concrete-free: Eliminates the need for concrete, making the installation process cleaner and more sustainable.

- No dewatering required: Suitable for wet environments without the need for dewatering, simplifying the process.

- Immediate load application: Ready for immediate loading upon installation, expediting project timelines.

- Easy load testing: Can be easily load tested during installation to verify capacity and ensure reliability.

- Reusability: Helical piles can be removed and relocated, making them ideal for temporary structures and applications.

- No vibrations: Installation causes no vibrations, making it suitable for sensitive environments and adjacent structures.

- Low headroom installations: Ideal for projects with height restrictions or confined spaces.

- Limited access installations: Can be installed in tight or restricted areas with minimal disruption.

- Capacity verification: Installation torque can be used to verify the pile’s capacity, providing confidence in its performance.

- Year-round installation: Can be installed in any weather conditions, ensuring project continuity and reliability.

- Sustainable foundations: Helical foundations can be removed and reused, offering an eco-friendly solution for temporary applications.

- Minimal disruption: Installation causes minimal damage and disruption, making helical piles ideal for remedial work in existing structures.