Call Anytime

How it works

Earthwise Helps You

Through The Process

Learn more about the SIP building process and feel better prepared for your upcoming new construction projects.

We'll first get to know each other, & make sure Earthwise is a solid fit for your construction project.

Next, we will engage in interactive online design meetings to ensure your goals are met.

Your plans will be engineered to ensure all the local code requirements are satisfied.

Your materials are prefabricated per plans, and a delivery scheduled.

At Earthwise Manufacturing, we initiate the SIP fabrication process by thoroughly understanding your project's requirements, objectives, and specifications. This crucial phase involves in-depth discussions and assessments to ensure we have a comprehensive understanding of your needs.

We are ready to help you

Once the design agreement is signed, your project will be added to our design queue, and we will commence scheduling our initial design meeting. During this crucial stage, you will have the opportunity to meet your dedicated designer, who will guide your project from start to finish.

We will thoroughly review the information provided by your Earthwise Project Manager, who will also participate in the meeting, ensuring complete alignment among all stakeholders. Together, as a cohesive team, you will collaborate with your designer and project manager to establish and solidify all essential criteria, paving the way for the commencement of the initial plans.

The initial design meeting is typically conducted online using video conferencing software, allowing us to have face-to-face interactions, regardless of your location within the United States.

During this phase, our dedicated designers collaborate closely with our window and door representatives to ensure that every SIP component of your home is meticulously designed to exact specifications, ready for seamless assembly.

Internally, we conduct a comprehensive review of every element, from the foundation to the roof, ensuring the readiness of our SIP System for structural engineering. This meticulous process includes the precise specification of all window and door openings, along with the creation of SIP shop drawings to guarantee the integrity of the SIP system.

Once the internal review is successfully completed, your plans are poised for the structural engineering phase.

We provide Engineering Services for all 50 states, ensuring that your plans conform to all local building code requirements, whether or not a permit is required for your construction project. These requirements encompass considerations such as seismic zones, snow loads, wind loads, and soil pressure bearing specific to your foundation. While the engineering phase may appear relatively quiet, it offers an excellent opportunity to look into your county's permit requirements.

We are ready to help you

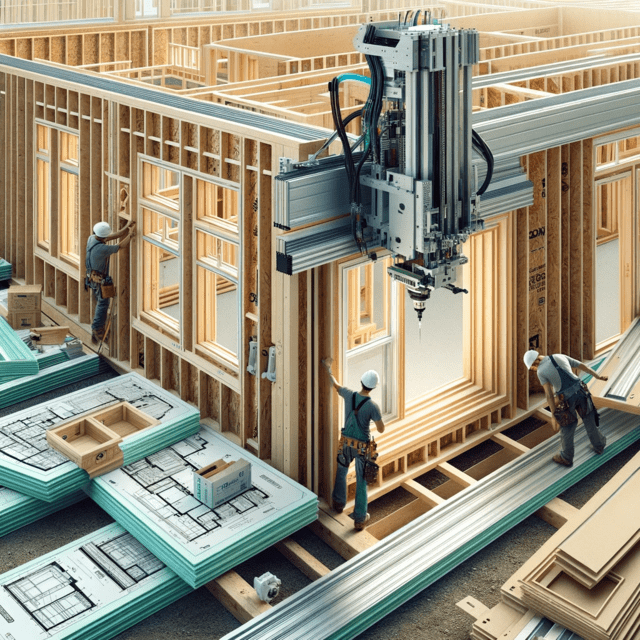

The exterior structural insulated panels (SIPs) are meticulously crafted using a CNC (computer numerical control) machine, programmed to match the unique specifications of your design. This advanced technology plays a crucial role in ensuring that each panel is cut with high precision. The accuracy of the CNC machine is pivotal in maintaining the integrity of the SIPs, as it ensures that all components, including the critical window and door cutouts, align perfectly with the architectural plans.

These cutouts are particularly important as they must match the dimensions and locations of the windows and doors specified in your design. The CNC machine's precision eliminates guesswork, ensuring that these openings are of the exact size and in the correct position, which is essential for a seamless installation of windows and doors later in the construction process.

Your dedicated Earthwise Project Manager will establish contact with both you and your builder to coordinate the delivery of your SIPs.

Typically, the roof and wall components will be the first to arrive at the job site. Ideally, the foundation has already been poured, and the construction crew is ready to begin assembling the package as soon as the delivery truck arrives.

We carefully stagger the delivery of these components to maintain an organized and efficient job site, preventing unnecessary clutter or congestion with materials.

If you'd like to dive deeper into the details, don't hesitate to reach out. We're always here for a chat and happy to assist with any inquiries you may have.